BACK UP, DATA RECOVERY AND SYSTEM CARE

Back up, Data recovery and system care

Windows back up options and utility

What to back up

Before you can know how you should best back up, you must know what you need to back up. The choice is ultimately yours, but I recommend protecting anything you might want or require later that you can’t re-create: electronic documents (tax stuff, business stuff, any hard copies you’ve scanned and discarded), artistic creations, memorabilia (photos, videos, your old band recordings), or pretty much anything whose loss would evoke extreme negative emotions. Wondering about your downloaded movies, music, and other purchased media? You can always download those items again later, though if you’re ambitious enough you can back them up as well. I don’t bother. Note that If your data is spread over multiple devices, you’ll need to

Asella Malt Factory was established on the main road of Addis Ababa to Asella near Kulumsa Agricultural Research Center with 9.3 million birr capital on 14.7 hectares of land in September 1/1984G.C. Location of Asella malt factory is 167km southern of Addis Ababa and 8km from Asella town in Kulumsa village. It was founded on the eve of the founding of workers party of Ethiopia and the tenth anniversary of the Ethiopia revolution. The factory was established with the aim of producing and providing malt for the existing breweries in the Country .The Factory was established in the region of potential malt barley producing zones namely: Arsi, Western Arsi, and Bale zones. The initial capacity of the factory was 100,000 quintal per annum whereas the demand of the breweries during this time was also nearest to the capacity. In 1983 E.C.(1991 G.C.) due to change of government of the country the barley producer of Asella malt factory became highly decreased their production and the agricultural governance to change their face to other grain like wheat which is give profit. Due to this reason the factory is suffering from shortage of barley. Then the factory to take measurement to decrease this problem to create relationship with the farmer which produce barley in the zone and to give selected crops of barley for farmer , for producer to give training and extension service and for barley to give equal reasonable value(price) like other grain. Due to this reason the factory gradually decreases shortage of barley year to year. In other word in the past time the number of the country of brewery factory is very small but today due to expansion of new private brewery factory the malt production necessity is increase in higher stage in our country. After down fall of the Dergi regime in 1991G.C (1983 E.C) and the followed free market policy, establishment of new breweries and expansion of the existing breweries create a rising demand for malt products. In response to this growing demand, the factory went through its first expansion to increase its annual production from 100,000 quintal per year to 150,000 quintal per year in December 1995 G.C. This production capacity can cover approximately 35-40 percent of the breweries’ demand at that time whereas the remaining 60-65 percent of malt requirement had been fulfilled by import which exhausting the country’s foreign currency reserves. With the aim of satisfying domestic demand of malt, the factory had been implemented its second and third expansion project during 2010-2012G.C. to increase its production capacity from 150,000 quintals to 360,000 quintals per annum and begin its production capacity of the factory by about 140% than before. In 2000E.C.(2008G.C.) the top management of Asella malt factory is committed to increase capacity of malt production implementing the second expansion project by 44,308,651 of Ethiopian birr in 2002E.C.(2010G.C). Then the factory is increasing their capacity of production from 150,000 quintal/year to 220,000quintal/year. In the 2003E.C (2011G.C) in the summer time the company implementing the third expansion project to increase capacity of production to 360,000 quintal/year. Time of finishing of this expansion project is 2004 E.C (2012G.C) and starting to work production. Even though the production capacity of the factory has been increased to this extent, it can cover only 55% of domestic breweries malt and demand because of continues expansion of domestic breweries’ capacity. Asella malt factory is continuous to increase capacity production like this and creating awareness to raw barley suppliers to produce and supply the necessary quantity and quality products. Also raw barley during purchased to establish management policy of quality and to produce quality of malt which is full requirement of brewery factory of the country. Additionally, to support any investigator (scientific study) of barley production by budget, for barley producer farmer to give extension service, to participate in protection of natural resource, to participate in school expansion, to help orphan children which is lost their family by HIV AIDS, participate in road expansion, and to participate in any development bazaar and sports to support and appreciate for sustainable development of the country. Asella malt factory to achieve their aims in 2003E.C (2011G.C) budget of year for implementation of new foster development for achievement of this goal starting work by one top manager, by four administration, by five legal service to work together and under this organization 43 professional, 48 secondary professional, 83 worker have learned secondary elementary stage of education finished, 49 worker which have been learned 1-8 grade to start work by constant worker and by daily employee. Generally, Asella malt factory to create work opportunity for around 230 employees (citizen). From this employee 126 is constant worker. Now days, the Factory needs more than 600,000 quintals of raw malt barley per annum to produce 360,000 quintals of malt in the year. The factory could not get that amount of quality malt barley in local market to utilize its annual capacity. Thus, to minimize the shortage of malt barley in the local market, the factory has been under taking different types of measure in collaboration with different stoke holders. Even though the factory has been trying to technical support for producers since 2007, the factory is still facing shortage of malt barley both in quality and quantity. Delivering quality goods and services can be a major target of any company to stay in competitive market. In response to the factory has been conducting different types of reform such as, Total Quality Management (TQM), Integrated Performance Measure System (IPMS), Kaizen, Business Process Reengineering (BPR) and Management Information System to improve its system. The implementation of these systems enabled the factory to improve its productivity and quality of its product. At the end of 2004, the factory has 54 professionals, 82 semi-professionals and 115 non-professional employees. Out of these workers and employees of whom approximately a quarter are women. This factory produces the malt from barley which is the major raw material for beer production. Other materials such as wheat, rye, sorghum or millet can also be used to produce malt. Of all the possible raw materials, barley has produced to be the most suitable malt for beer production. Asella Malt Factory has supplying barley malt to domestic brewery factory in high quality and quantity. The factory is trying to profit the country economic development by producing malt which is imported to the country which it saves foreign currency. The main customers of Asella malt factory are brewery factories. Among them: St. Georges (BGI) Harar brewery factory Raya brewery factory Bedale brewery factory Meta brewery factory The factory plans three year strategic plan by applying in action and participate on it. By this plan the factories vision, mission and selected strategic targets are organized. Producing universally standardized quality malt production and transfer the country’s foreign market supply. To fulfill quality policy of the World. To supply inside the country, outside the country and become famous malt factory. To produce malt and increase supply quality to give support for investigator (researcher) of barley for achievement of the goal. By using modern technology to fulfill quality policy of the World to produce quality malt. To become famous malt producer in the World to save economy of country which is purchased malt from foreign country and to take responsibility development of the country. Quality, Accountability, justices and Loyalty are the assets of the company. Quality service and assuring remarks are the measures of success. Focus on developmental activities that participates all society. Follow best management method to use assets. Work together and the success or the failure will be ours. Following professional ethics is our quality. Giving more priority for customers and satisfying their needs. Concern for the quality of malt. Sustaining profitability and productivity Asella Malt Factory designed three year strategic plan. Based on this plan the factory tries to increase current production capacity in quality and improve the quality. By the time the factory is supplying excess product to the market and improving it selling activity. The main issues the factories success profit at the moment is strategic plan and minimizing production cost. Asella Malt Factory has done many successful events from those activities some are the following. The factory sees itself first and foremost as part of local community. It believes that the health and wellbeing of the community and health of the factory are linked together as the company’s profitability is depend on the wellbeing of its work force and barley producer farmers. The factory believes it has the responsibility to support community led initiatives. Among its many community based programs some are the construction, equipment of schools, construction of coble stone roads in Asella town, rural gravel road, provision of ambulance to support Red Cross service in the vicinity, reforestation program and so on. In the case of the factories ICT service the factory is working with 85 computers and organized into 2 servers with LAN networking for internal information flow. In addition to this internet service for the company about 24 hours a day with great fiber optics with 5 megabyte per second speed. This allows controlling the current malt barley domestic and foreign business issues. Asella Malt Factory was established on the main road of Addis Ababa to Asella near Kulumsa Agricultural Research Center with 9.3 million birr capital on 14.7 hectares of land in September 1/1984G.C. Location of Asella malt factory is 167km southern of Addis Ababa and 8km from Asella town in Kulumsa village. It was founded on the eve of the founding of workers party of Ethiopia and the tenth anniversary of the Ethiopia revolution. The factory was established with the aim of producing and providing malt for the existing breweries in the Country .The Factory was established in the region of potential malt barley producing zones namely: Arsi, Western Arsi, and Bale zones. The initial capacity of the factory was 100,000 quintal per annum whereas the demand of the breweries during this time was also nearest to the capacity. In 1983 E.C.(1991 G.C.) due to change of government of the country the barley producer of Asella malt factory became highly decreased their production and the agricultural governance to change their face to other grain like wheat which is give profit. Due to this reason the factory is suffering from shortage of barley. Then the factory to take measurement to decrease this problem to create relationship with the farmer which produce barley in the zone and to give selected crops of barley for farmer , for producer to give training and extension service and for barley to give equal reasonable value(price) like other grain. Due to this reason the factory gradually decreases shortage of barley year to year. In other word in the past time the number of the country of brewery factory is very small but today due to expansion of new private brewery factory the malt production necessity is increase in higher stage in our country. After down fall of the Dergi regime in 1991G.C (1983 E.C) and the followed free market policy, establishment of new breweries and expansion of the existing breweries create a rising demand for malt products. In response to this growing demand, the factory went through its first expansion to increase its annual production from 100,000 quintal per year to 150,000 quintal per year in December 1995 G.C. This production capacity can cover approximately 35-40 percent of the breweries’ demand at that time whereas the remaining 60-65 percent of malt requirement had been fulfilled by import which exhausting the country’s foreign currency reserves. With the aim of satisfying domestic demand of malt, the factory had been implemented its second and third expansion project during 2010-2012G.C. to increase its production capacity from 150,000 quintals to 360,000 quintals per annum and begin its production capacity of the factory by about 140% than before. In 2000E.C.(2008G.C.) the top management of Asella malt factory is committed to increase capacity of malt production implementing the second expansion project by 44,308,651 of Ethiopian birr in 2002E.C.(2010G.C). Then the factory is increasing their capacity of production from 150,000 quintal/year to 220,000quintal/year. In the 2003E.C (2011G.C) in the summer time the company implementing the third expansion project to increase capacity of production to 360,000 quintal/year. Time of finishing of this expansion project is 2004 E.C (2012G.C) and starting to work production. Even though the production capacity of the factory has been increased to this extent, it can cover only 55% of domestic breweries malt and demand because of continues expansion of domestic breweries’ capacity. Asella malt factory is continuous to increase capacity production like this and creating awareness to raw barley suppliers to produce and supply the necessary quantity and quality products. Also raw barley during purchased to establish management policy of quality and to produce quality of malt which is full requirement of brewery factory of the country. Additionally, to support any investigator (scientific study) of barley production by budget, for barley producer farmer to give extension service, to participate in protection of natural resource, to participate in school expansion, to help orphan children which is lost their family by HIV AIDS, participate in road expansion, and to participate in any development bazaar and sports to support and appreciate for sustainable development of the country. Asella malt factory to achieve their aims in 2003E.C (2011G.C) budget of year for implementation of new foster development for achievement of this goal starting work by one top manager, by four administration, by five legal service to work together and under this organization 43 professional, 48 secondary professional, 83 worker have learned secondary elementary stage of education finished, 49 worker which have been learned 1-8 grade to start work by constant worker and by daily employee. Generally, Asella malt factory to create work opportunity for around 230 employees (citizen). From this employee 126 is constant worker. Now days, the Factory needs more than 600,000 quintals of raw malt barley per annum to produce 360,000 quintals of malt in the year. The factory could not get that amount of quality malt barley in local market to utilize its annual capacity. Thus, to minimize the shortage of malt barley in the local market, the factory has been under taking different types of measure in collaboration with different stoke holders. Even though the factory has been trying to technical support for producers since 2007, the factory is still facing shortage of malt barley both in quality and quantity. Delivering quality goods and services can be a major target of any company to stay in competitive market. In response to the factory has been conducting different types of reform such as, Total Quality Management (TQM), Integrated Performance Measure System (IPMS), Kaizen, Business Process Reengineering (BPR) and Management Information System to improve its system. The implementation of these systems enabled the factory to improve its productivity and quality of its product. At the end of 2004, the factory has 54 professionals, 82 semi-professionals and 115 non-professional employees. Out of these workers and employees of whom approximately a quarter are women. This factory produces the malt from barley which is the major raw material for beer production. Other materials such as wheat, rye, sorghum or millet can also be used to produce malt. Of all the possible raw materials, barley has produced to be the most suitable malt for beer production. Asella Malt Factory has supplying barley malt to domestic brewery factory in high quality and quantity. The factory is trying to profit the country economic development by producing malt which is imported to the country which it saves foreign currency. The main customers of Asella malt factory are brewery factories. Among them: St. Georges (BGI) Harar brewery factory Raya brewery factory Bedale brewery factory Meta brewery factory The factory plans three year strategic plan by applying in action and participate on it. By this plan the factories vision, mission and selected strategic targets are organized. Producing universally standardized quality malt production and transfer the country’s foreign market supply. To fulfill quality policy of the World. To supply inside the country, outside the country and become famous malt factory. To produce malt and increase supply quality to give support for investigator (researcher) of barley for achievement of the goal. By using modern technology to fulfill quality policy of the World to produce quality malt. To become famous malt producer in the World to save economy of country which is purchased malt from foreign country and to take responsibility development of the country. Quality, Accountability, justices and Loyalty are the assets of the company. Quality service and assuring remarks are the measures of success. Focus on developmental activities that participates all society. Follow best management method to use assets. Work together and the success or the failure will be ours. Following professional ethics is our quality. Giving more priority for customers and satisfying their needs. Concern for the quality of malt. Sustaining profitability and productivity Asella Malt Factory designed three year strategic plan. Based on this plan the factory tries to increase current production capacity in quality and improve the quality. By the time the factory is supplying excess product to the market and improving it selling activity. The main issues the factories success profit at the moment is strategic plan and minimizing production cost. Asella Malt Factory has done many successful events from those activities some are the following. The factory sees itself first and foremost as part of local community. It believes that the health and wellbeing of the community and health of the factory are linked together as the company’s profitability is depend on the wellbeing of its work force and barley producer farmers. The factory believes it has the responsibility to support community led initiatives. Among its many community based programs some are the construction, equipment of schools, construction of coble stone roads in Asella town, rural gravel road, provision of ambulance to support Red Cross service in the vicinity, reforestation program and so on. In the case of the factories ICT service the factory is working with 85 computers and organized into 2 servers with LAN networking for internal information flow. In addition to this internet service for the company about 24 hours a day with great fiber optics with 5 megabyte per second speed. This allows controlling the current malt barley domestic and foreign business issues. CHAPTER ONE

INTRODUCTION

1.1 Brief History of Asella Malt Factory

1.2 It’s Main Products and Services

1.3 The Main Customers of the Company

1.4 Vision

1.5 mission

1.6 Value of the Company

1.7 Strategies

READ FULL DOCUMENT BELOW

CHAPTER ONE

INTRODUCTION

1.1 Brief History of Asella Malt Factory

1.2 It’s Main Products and Services

1.3 The Main Customers of the Company

1.4 Vision

1.5 mission

1.6 Value of the Company

1.7 Strategies

READ FULL DOCUMENT BELOW

Though not strictly necessary, it is especially convenient to have a complete backup of your desktop or laptop (ideally with your mobile-device data on board), as described in Method B. It’s by far the quickest and easiest way to restore your operating system, applications, and data, should your system succumb to hard-drive failure or a malware attack. This procedure is referred to as disaster recovery, and it requires a boot disc/flash drive created by the backup/recovery software. Without a disaster-recovery backup, you’ll wind up restoring the operating system and applications individually from scratch.

Where to back it up

This is an easy one. I’m going out on a limb here and guessing that you don’t have a tape backup drive. You may not even have an optical drive. If you do, there’s nothing wrong with keeping a backup or two on disc, but that’s your concern. I think old technology that slows down the process stifles motivation.

If your broadband connection has enough upstream bandwidth, back up to an online file-hosting service. Using such a service is pay-to-play, but costs a fraction of what it costs to recover data from a failed hard drive. It’s also ridiculously easy—you just set it and forget it.

Obviously, many people don’t have sufficient upstream bandwidth, or a data set small enough to make the online option viable as a complete solution. In that case, reduce your backup set (what you select to back up—don’t remove the data itself) to the bare minimum, keep it online, and then back up the rest locally using storage drives you attach to your computer or network.

For local backups, use an external USB 3.0/eSATA/FireWire/Thunderbolt drive, or if the data set is small, use a USB 3.0 flash drive, also known as a thumb drive. Use two drives and alternate between them if you don’t plan to back up online, or ideally, even if you do. With hard-drive space costing about 5 cents a gigabyte, and flash costing about 60 cents per gigabyte currently, you can afford it. Don’t use USB 2.0 unless you have to: It’s slow—and once again, older technology demotivates.

Alternatively, you could use a network-attached storage box. Gigabit Ethernet is as fast as USB 3.0, and a NAS box lets you back up multiple computers on a network without having to drag a box from location to location. Most NAS boxes support rsync, which allows you to mirror one to another in a remote location (such as your aunt’s house)—a possible alternative to online backup.

How to back it up

Ah, the nitty-gritty. Here’s how to back up once you have your backup repository (a hard drive or other device) and/or service in place.

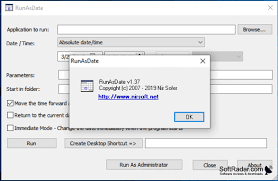

First, select your disaster-recovery and backup software. Windows 7 and 8 both offer integrated applications that can create complete system-recovery images, though in Windows 8 it’s somewhat hidden under Control Panel > All Items > Windows 7 File Recovery. Alas, the restore routine isn’t particularly robust, and it can fail with as simple a change in hardware as replacing your hard drive with a smaller solid-state drive. In this case, you can still have the PC mount the system image as a virtual hard drive, but only after reinstalling the operating system manually.

Once you decide on the software, the basic procedure is as follows:

Run the software.

Select the destination for the system backup. This will be the external drive you purchased as a backup repository, a NAS box, or even a shared location on another PC.

Select the partitions (C:, D:, or the like) that you want to back up. You should select all of them the first time around, excluding the destination drive for the backup. (Most backup software prevents you from selecting the destination partition/drive.)

Run the backup process.

When the process is finished, put the backup media in a safe place (if applicable).

Create your recovery media (CD/DVD/thumb drive).

For backing up just your data, Windows has its own capable backup application, but you can find dozens of backup programs that are easier or more versatile, including notables such as Acronis Backup & Recovery and True Image, Easeus Todo Backup, Genie Timeline Backup, and NovaBackup. If you’re using an online service, the service will provide a backup application. Most of the time it’ll create a local backup on your external hard drive at the same time it backs up online.

If you want something more along the lines of Apple’s elegant and easy-to-use Time Machine (which combines full system backup with data backup), Genie Timeline may be what you seek. You’ll also find continuous backup products, such as Stardock’s KeepSafe, which perform a full data backup (no OS or applications) and then look for and back up changed files at short intervals Asella Malt Factory was established on the main road of Addis Ababa to Asella near Kulumsa Agricultural Research Center with 9.3 million birr capital on 14.7 hectares of land in September 1/1984G.C. Location of Asella malt factory is 167km southern of Addis Ababa and 8km from Asella town in Kulumsa village. It was founded on the eve of the founding of workers party of Ethiopia and the tenth anniversary of the Ethiopia revolution. The factory was established with the aim of producing and providing malt for the existing breweries in the Country .The Factory was established in the region of potential malt barley producing zones namely: Arsi, Western Arsi, and Bale zones. The initial capacity of the factory was 100,000 quintal per annum whereas the demand of the breweries during this time was also nearest to the capacity. In 1983 E.C.(1991 G.C.) due to change of government of the country the barley producer of Asella malt factory became highly decreased their production and the agricultural governance to change their face to other grain like wheat which is give profit. Due to this reason the factory is suffering from shortage of barley. Then the factory to take measurement to decrease this problem to create relationship with the farmer which produce barley in the zone and to give selected crops of barley for farmer , for producer to give training and extension service and for barley to give equal reasonable value(price) like other grain. Due to this reason the factory gradually decreases shortage of barley year to year. In other word in the past time the number of the country of brewery factory is very small but today due to expansion of new private brewery factory the malt production necessity is increase in higher stage in our country. After down fall of the Dergi regime in 1991G.C (1983 E.C) and the followed free market policy, establishment of new breweries and expansion of the existing breweries create a rising demand for malt products. In response to this growing demand, the factory went through its first expansion to increase its annual production from 100,000 quintal per year to 150,000 quintal per year in December 1995 G.C. This production capacity can cover approximately 35-40 percent of the breweries’ demand at that time whereas the remaining 60-65 percent of malt requirement had been fulfilled by import which exhausting the country’s foreign currency reserves. With the aim of satisfying domestic demand of malt, the factory had been implemented its second and third expansion project during 2010-2012G.C. to increase its production capacity from 150,000 quintals to 360,000 quintals per annum and begin its production capacity of the factory by about 140% than before. In 2000E.C.(2008G.C.) the top management of Asella malt factory is committed to increase capacity of malt production implementing the second expansion project by 44,308,651 of Ethiopian birr in 2002E.C.(2010G.C). Then the factory is increasing their capacity of production from 150,000 quintal/year to 220,000quintal/year. In the 2003E.C (2011G.C) in the summer time the company implementing the third expansion project to increase capacity of production to 360,000 quintal/year. Time of finishing of this expansion project is 2004 E.C (2012G.C) and starting to work production. Even though the production capacity of the factory has been increased to this extent, it can cover only 55% of domestic breweries malt and demand because of continues expansion of domestic breweries’ capacity. Asella malt factory is continuous to increase capacity production like this and creating awareness to raw barley suppliers to produce and supply the necessary quantity and quality products. Also raw barley during purchased to establish management policy of quality and to produce quality of malt which is full requirement of brewery factory of the country. Additionally, to support any investigator (scientific study) of barley production by budget, for barley producer farmer to give extension service, to participate in protection of natural resource, to participate in school expansion, to help orphan children which is lost their family by HIV AIDS, participate in road expansion, and to participate in any development bazaar and sports to support and appreciate for sustainable development of the country. Asella malt factory to achieve their aims in 2003E.C (2011G.C) budget of year for implementation of new foster development for achievement of this goal starting work by one top manager, by four administration, by five legal service to work together and under this organization 43 professional, 48 secondary professional, 83 worker have learned secondary elementary stage of education finished, 49 worker which have been learned 1-8 grade to start work by constant worker and by daily employee. Generally, Asella malt factory to create work opportunity for around 230 employees (citizen). From this employee 126 is constant worker. Now days, the Factory needs more than 600,000 quintals of raw malt barley per annum to produce 360,000 quintals of malt in the year. The factory could not get that amount of quality malt barley in local market to utilize its annual capacity. Thus, to minimize the shortage of malt barley in the local market, the factory has been under taking different types of measure in collaboration with different stoke holders. Even though the factory has been trying to technical support for producers since 2007, the factory is still facing shortage of malt barley both in quality and quantity. Delivering quality goods and services can be a major target of any company to stay in competitive market. In response to the factory has been conducting different types of reform such as, Total Quality Management (TQM), Integrated Performance Measure System (IPMS), Kaizen, Business Process Reengineering (BPR) and Management Information System to improve its system. The implementation of these systems enabled the factory to improve its productivity and quality of its product. At the end of 2004, the factory has 54 professionals, 82 semi-professionals and 115 non-professional employees. Out of these workers and employees of whom approximately a quarter are women. This factory produces the malt from barley which is the major raw material for beer production. Other materials such as wheat, rye, sorghum or millet can also be used to produce malt. Of all the possible raw materials, barley has produced to be the most suitable malt for beer production. Asella Malt Factory has supplying barley malt to domestic brewery factory in high quality and quantity. The factory is trying to profit the country economic development by producing malt which is imported to the country which it saves foreign currency. The main customers of Asella malt factory are brewery factories. Among them: St. Georges (BGI) Harar brewery factory Raya brewery factory Bedale brewery factory Meta brewery factory The factory plans three year strategic plan by applying in action and participate on it. By this plan the factories vision, mission and selected strategic targets are organized. Producing universally standardized quality malt production and transfer the country’s foreign market supply. To fulfill quality policy of the World. To supply inside the country, outside the country and become famous malt factory. To produce malt and increase supply quality to give support for investigator (researcher) of barley for achievement of the goal. By using modern technology to fulfill quality policy of the World to produce quality malt. To become famous malt producer in the World to save economy of country which is purchased malt from foreign country and to take responsibility development of the country. Quality, Accountability, justices and Loyalty are the assets of the company. Quality service and assuring remarks are the measures of success. Focus on developmental activities that participates all society. Follow best management method to use assets. Work together and the success or the failure will be ours. Following professional ethics is our quality. Giving more priority for customers and satisfying their needs. Concern for the quality of malt. Sustaining profitability and productivity Asella Malt Factory designed three year strategic plan. Based on this plan the factory tries to increase current production capacity in quality and improve the quality. By the time the factory is supplying excess product to the market and improving it selling activity. The main issues the factories success profit at the moment is strategic plan and minimizing production cost. Asella Malt Factory has done many successful events from those activities some are the following. The factory sees itself first and foremost as part of local community. It believes that the health and wellbeing of the community and health of the factory are linked together as the company’s profitability is depend on the wellbeing of its work force and barley producer farmers. The factory believes it has the responsibility to support community led initiatives. Among its many community based programs some are the construction, equipment of schools, construction of coble stone roads in Asella town, rural gravel road, provision of ambulance to support Red Cross service in the vicinity, reforestation program and so on. In the case of the factories ICT service the factory is working with 85 computers and organized into 2 servers with LAN networking for internal information flow. In addition to this internet service for the company about 24 hours a day with great fiber optics with 5 megabyte per second speed. This allows controlling the current malt barley domestic and foreign business issues. CHAPTER ONE

INTRODUCTION

1.1 Brief History of Asella Malt Factory

1.2 It’s Main Products and Services

1.3 The Main Customers of the Company

1.4 Vision

1.5 mission

1.6 Value of the Company

1.7 Strategies

READ FULL DOCUMENT BELOW

After you’ve installed your software, follow these steps:

Run the software.

Select the files and folders you want to back up.

Select the destination for the system backup. This will be the external drive you purchased as a backup repository, a NAS box, a shared location on another PC, and/or your online backup service.

Run the backup process. (Make a full backup of all your data the first time.)

Verify the backup.

When the backup process is finished, put the backup media in a safe place (if applicable).

Repeat as necessary—daily, weekly, or monthly, depending on how often things change and how risk-averse you are.

Tip: After your initial full backup, perform incremental backups (backing up only the changes since the last backup) or differential backups (backing up all changed files since the initial full backup) to save time. Start over with a new full backup once a week if you’re backing up daily, once a month if you’re backing up weekly, or once every four to six months if you’re backing up monthly. Note: Never, ever delete the old backup until the new one is finished.

Step 7 and the tip above describe what are affectionately known as backup methodologies. There are far more complex ones, but complexity, like slow technology, demotivates. (Unless, of course, you’re being paid a lot to back up something. I’m guessing you’re not, if you’re reading this primer.)

Getting the data off your devices

Although free online backup and storage space is available for each major mobile platform (5GB for iOS/iCloud, 15GB for Android/Google Drive, 7GB for Windows Phone/SkyDrive), centralizing the data from all your devices can be a tad more complicated. With Google Drive and SkyDrive, you get local copies of your files on your PC if you install their respective apps. Just add those files to your list of locations to back up, and you’re golden. Or, you can simply copy stuff over from the appropriate folder when the device is attached to your PC via USB.

Comments

Post a Comment